The plastic trash clash

Nature on a plastic diet

Recycling with the help of micro-organisms

By Esmée Janssen, 6 April 2022

Last autumn, the very first waste processing plant to use plastic-degrading enzymes from fungi opened in France. This method is revolutionary because the enzymes convert the plastic back into the building blocks it is made of. From these building blocks you can produce plastic again. So we have a sustainable way of breaking down plastic and producing it again. These plastic-degrading enzymes appear to be a promising solution to the current plastic problem.

Almost 400 million tonnes of plastic are produced every year. Large quantities of plastic end up in nature. However, nowadays we can also find all kinds of organisms in nature that can break down this plastic. Fungi, bacteria and even worms have been found that incorporate plastic into their diet. These plastic-degrading species are also called plastivores.

To break down plastic, plastivores use enzymes. Enzymes break down the large polymers from which plastic is made into smaller particles. An enzyme has been found that can break down all types of plastic, from plastic bags to what we put in our mattresses. Some plastics are easier to break down than others. How complicated the degradation process is, depends on the composition of the plastic. For example, your plastic bottle is easier to break down than your plastic bag.

Plastivores did not always exist, but have arisen over time along with the rise of plastics. There will probably only be more plastic-degrading organisms in nature. At least, that is the expectation of Jo-Anne Verschoor, researcher at Leiden University. Jo-Anne does research on plastic-degrading enzymes and even won the Unilever research prize for this in 2020. According to Jo-Anne, there is a good chance that organisms will emerge that can break down plastic much faster and better than they can now. This is because we have only been using plastic in really large quantities for about 70 years. However, she also thinks that we underestimate how many species there already are that can break down plastic, as we can only examine 1% of all micro-organisms properly in the lab.

We can use the emergence of these plastivores to our advantage. We currently have about 150 million tonnes of plastic waste in our oceans and no good way of breaking it down. All the plastic floating around in nature is slowly being broken down into very small plastic particles called microplastics. The microplastics then end up in our own drinking water. At present, we do not have a good method of purifying these tiny plastic particles from water. If we were to use the plastivores in a water purification installation, we could eventually filter all microplastics out of the water.

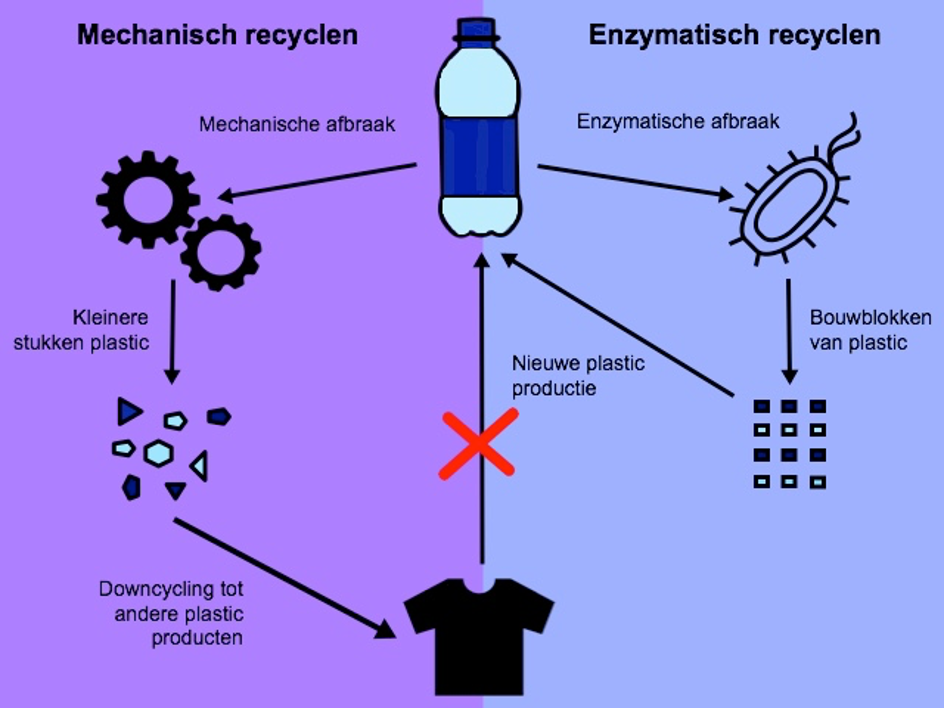

In addition, we could use the plastivores in waste processing plants to clean up our waste. With the enzymes from the plastivores, we can break down plastic into the building blocks it is made of. So we can produce new plastic from them. This so-called enzymatic recycling thus creates a circular economy, in which we do not exhaust new raw material reserves. Very sustainable!

“I believe in many ways that micro-organisms, or nature at all, could be our answer.” – Jo-Anne

Achieving a fully circular economy is groundbreaking within the plastic recycling industry. “Until now, all solutions have been mechanical or chemical, which gives lower quality products, is expensive and takes a lot of energy,” says Jo-Anne. Currently, we recycle most plastics by mechanical recycling. In mechanical recycling, plastic is first ground up and then melted into smaller pieces. In feedstock recycling, a chemical reaction is used to break down the plastic. A major advantage of an enzymatic degradation method is that it does not result in so-called downcycling as current recycling methods do.

However, enzymatic recycling is still very much in its infancy. It is currently very difficult to set up on a large scale. The enzymes are not yet efficient enough to convert a lot of plastic in a short time. At the moment we can simply convert much more mechanically than enzymatically, so unfortunately it cannot compete with the current methods.

In addition, recycling plastic by means of enzymes is not yet as cost-effective as producing plastic from new raw material. There are ways of making it more effective, however. Jo-Anne is working on this in her research. She is doing this, for example, by investigating what the optimum conditions are for the enzymes that the plastivores secrete. She is also looking for new enzymes that can break down several types of plastic at the same time. Moreover, most plastics are now made from oil. If oil prices continue to rise and we make enzymatic recycling more and more productive, we may be able to compete in the future with current policies in terms of cost.

So enzymatic recycling looks promising. But we need to keep investing in more research on enzymatic recycling to optimise it. The research field is still very young, so there is still a lot of room for improvement. However, many steps are already being taken in the right direction. For instance, the French company Carbios was the first to apply enzymatic recycling on a large industrial scale. If we continue to research and optimise the technique, we may see more companies like Carbios in the future.

Sources

Articles:

Carbios. (2022). Carbios to build in France its first-of-a-kind manufacturing plant for fully bio-recycled PET in partnership with Indorama Ventures. Retrieved 20 March 2022, from https://www.carbios.com/en/carbios-to-build-in-france-its-plant/

Carbios. (2021). Carbios launches industrial demonstration plant for its unique enzymatic recycling technology. Retrieved 20 March 2022, from https://www.carbios.com/en/carbios-annonce-le-demarrage-de-son-demonstrateur-industriel-exploitant-sa-technologie-unique-de-recyclage-enzymatique-c-zyme/

Danso, D., Chow, J., & Streit, W. R. (2019). Plastics: environmental and biotechnological perspectives on microbial degradation. Applied and environmental microbiology, 85(19), e01095-19.

Faraca, G., & Astrup, T. (2019). Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Management, 95, 388-398.

Othman, A. R., Hasan, H. A., Muhamad, M. H., Ismail, N. I., & Abdullah, S. R. S. (2021). Microbial degradation of microplastics by enzymatic processes: a review. Environmental Chemistry Letters, 19 (4), 3057-3073.

Stubbins, A., Law, K. L., Muñoz, S. E., Bianchi, T. S., & Zhu, L. (2021). Plastics in the Earth system. Science, 373(6550), 51-55.

Thiyagarajan, S., Maaskant-Reilink, E., Ewing, T. A., Julsing, M. K., & van Haveren, J. (2022). Back-to-monomer recycling of polycondensation polymers: opportunities for chemicals and enzymes. RSC Advances, 12 (2), 947-970.

Verschoor, J.A., Kusumawardhani, H., Ram, A.F., & De Winde, J.H. (2022). Towards microbial recycling and upcycling of plastics: prospects and challenges. Frontiers in Microbiology, 701.

Yuan, J., Ma, J., Sun, Y., Zhou, T., Zhao, Y., & Yu, F. (2020). Microbial degradation and other environmental aspects of microplastics/plastics. Science of the Total Environment, 715, 136968.

Zrimec, J., Kokina, M., Jonasson, S., Zorrilla, F., & Zelezniak, A. (2021). Plastic-degrading potential across the global microbiome correlates with recent pollution trends. MBio, 12 (5), e02155-21.