Sustainable products

From sewage to bioplastic

By Jaap Langenhoff

Have you ever wondered what will happen with your excrement after flushing the toilet? The fact that it might turn into a ready to use toothbrush made from plastic would probably come as a surprise. According to scientists from the Wider business Opportunities for raw materials from Wastewater (WOW) project, sewage contains a lot of valuable components which can be converted into bioplastics by using state of the art technologies.

But why would scientists crack their brains over turning sewage into plastic when making plastic from fossil oil is cheap, fast, and easy? They aim for a more circular and sustainable future. Since climate change is an inevitable fact of today’s reality, scientists from all over the world are searching for innovative ways to reduce our carbon footprint and the depletion of earth’s resources. Re-using chemicals and materials coming from waste streams have this potential. Professor Jappe de Best, lecturer biobased resources at Avans Hogeschool, and his research group are studying the utilization of waste streams. One of their main topics is to utilize sewage to produce polyhydroxyalkanoates (PHA). PHA are bio-polyesters, a group of bioplastics varying in physical proposition to construct materials with a wide range of properties. The most common type of PHA is poly-3-hydroxyburate (P3HB), which is used in disposable tableware articles like drinking cups, cutlery, trays, food plates and food containers. During the wastewater purification process, valuable chemicals derived from sewage are wasted, mostly burned. As a result, new resources have to be exploited in order to deliver on consumers’ demand. “It is a shame that valuable compounds are wasted”, says Jappe.

“It is a shame that valuable compounds are wasted.”

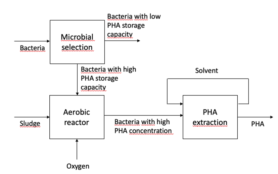

In conventional wastewater purification industries, bacteria are used in sewage treatment to reduce the volume of sludge (a semi-solid slurry present in sewage) and produce methane gas from it. In addition, these microorganisms can produce PHA from organic compounds such as sugars and fatty acids derived from sewage (Morgan-Sagastume et al., 2014). PHA is stored in microbial cells as a reserve source of energy which the bacteria itself can consume in times of food scarcity. PHA production is based on a bacteria mixed culture. Because this mixture variates in PHA storage capacity, microbial selection of microorganisms with high PHA storage capacity is required (Argiz et al., 2020). After the microbial selection, PHA production takes place in two steps. First, in an aerobic reactor (in the presence of oxygen) bacteria will convert organic compounds in sludge into PHA. Then, PHA is extracted from the microbial cells using an environmentally friendly solvent. This solvent can be re-used to make this an even more circular process. The PHA production scheme is shown in Figure 1, where sludge is derived from the wastewater purification process.

Figure 1: PHA production scheme

PHA has a high potential for usage in the agricultural sector, due to its fast degradability in nature. Amelia et al. (2019) describes three potentials for PHA usage in the agricultural sector: mulch films, agricultural nets, and agricultural bags. Mulching is used to maintain the quality of the soil. Therefore, two types of mulch are used namely natural and synthetic mulch. Among the synthetic mulch, plastic mulch is used extensively. Used mulch films will often end up on the land, in the soil or being burned with lots of pollution. Also, agricultural nets and bags are made of conventional plastics without the properties of natural degradation. Using PHA, as a product from sewage, for these applications can solve this problem. PHA is fully compostable and has similar physical properties as conventional plastics. Besides the agricultural sector, researchers are experimenting with using PHA for everyday life applications. Jappe believes that PHA will find more suitable applications in the future: “They made a lamp, using PHA and orange peelings.”

“They made a lamp, using PHA and orange peelings.”

However, the production of bioplastic from sewage comes with some major challenges. Small scale experiments have proven to be successful. Now the challenge is too upscale this process. A report released in 2017 introduced the outcomes of the Phario Pilot Project (Bengtsson et al., 2017), a PHA production experiment at the Bath wastewater purification plant. Once the pilot was completed, the project focused on upscaling the process and building a commercial factory to produce 2000 – 2500-ton PHA per year, treating wastewater from 500.000 people equivalents. Even though this project seems hopeful for future wastewater treatment, Jappe foresees big logistic challenges. To be a viable resource, the organic waste derived from sewage must be relatively abundant, concentrated and readily degradable. Not every wastewater purification plant has this capacity of resource. Let alone the fact that wastewater purification plants are not equipped with PHA-reactors and extraction tanks. Therefore, transportation is needed between wastewater purification plants and sludge treatment factories. A more efficient approach would be to cluster the wastewater purification plants. However, this includes big construction challenges and comes with high costs.

Brushing your teeth with a sewage derived toothbrush made from bio-PHA is possible with today’s technologies. However, everyday life usage of sewage based PHA is not yet realistic. Production costs are significantly higher in comparison to fossil oil-based plastics. This is mainly the result of the fact that the industry is not adapted to sewage treatment for PHA production. Jappe and his WOW research team are organizing conferences to promote the potential of their research to regional water authorities, researchers, plastic suppliers, and European- and national policy makers. They all need to work together for achieving a circular economy, with bio-PHA as the futures plastic.

Literature

Amelia, T. S. M., Govindasamy, S., Tamothran, A. M., Vigneswari, S., & Bhubalan, K. (2019). Applications of PHA in agriculture. In Biotechnological applications of polyhydroxyalkanoates (pp. 347-361). Springer, Singapore.

Argiz, L., Fra-Vázquez, A., Del Río, Á. V., & Mosquera-Corral, A. (2020). Optimization of an enriched mixed culture to increase PHA accumulation using industrial saline complex wastewater as a substrate. Chemosphere, 247, 125873.

Bengtsson, S., Werker, A., Visser, C., & Korving, L. (2017). PHARIO: stepping stone to a sustainable value chain for PHA bioplastic using municipal activated sludge. Stichting Toegepast Onderzoek Waterbeheer.

Morgan-Sagastume, F., Valentino, F., Hjort, M., Cirne, D., Karabegovic, L., Gerardin, F., … & Werker, A. (2014). Polyhydroxyalkanoate (PHA) production from sludge and municipal wastewater treatment. Water Science and Technology, 69(1), 177-184.