The development of artificial organs

Organs out of the printer in the fight against diabetes

Scientists from the Netherlands, Switzerland, Italy, Belgium and Sweden have received a joint grant to work on a new 3D printer. The researchers are building this new printer at the UMC Utrecht. This printer will print pancreatic tissue. Scientists then use this printed tissue to test drugs for diabetes.

At the age of twelve Robbert van Galen heard that he has diabetes. Since then, he has had to inject insulin several times a day. “Insulin is a hormone, and sometimes they are unpredictable. That sometimes makes it frustrating and tiring to always watch what you eat and do and how much insulin you have to inject.” says van Galen. Van Galen uses this to describe a problem that patients with diabetes face on a daily basis. These patients have to inject insulin several times a day throughout their lives. They do this to regulate the sugar level in their blood. The cells that regulate this in healthy people are broken in patients with diabetes. To stop this daily insulin injection, researchers are therefore looking for a one-time drug for diabetes.

Testing drugs is very annoying for patients. If a medicine does not work properly or has unpleasant side effects, this is not pleasant for the patient. In order not to bother patients with diabetes with this, the researchers from Utrecht first want to test the medicine outside the patient’s body. The Utrecht researchers are making a piece of pancreatic tissue for this. The pancreas contains the damaged cells in patients with diabetes. The researchers are testing the new drug on this pancreatic tissue. The researchers in Utrecht will ‘print’ this tissue with a 3D printer.

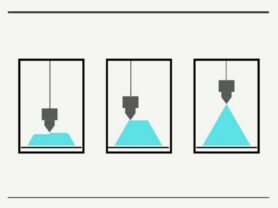

Classic 3D printers print layer by layer. The result builds up from bottom to top. This way of 3D printing is very time consuming. This process takes too long for printing living cells, also known as bioprinting. The living cells do not survive the lengthy process of classical 3D bioprinting. That is why the researchers in Utrecht are building a new 3D bioprinter that prints faster. This is called the volumetric 3D bioprinter. “With volumetric bioprinting, a similar piece of tissue is printed in tenths of a second,” says one of the Utrecht researchers, Davide Ribezzi.

| Figure 1: A classic 3D printer prints a pyramid. |

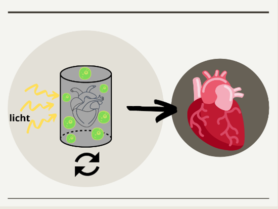

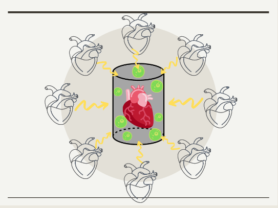

A volumetric bioprinter consists of a rotating tube containing a gel with cells. Some kind of laser light shines on this tube. The moment this light hits the gel, it hardens very quickly. The researchers make a kind of hologram of the tissue they want to print. They shine this hologram on the tube with the gel. The hologram hardens very quickly and the fabric is printed. The researchers are now first working on printing pieces of tissue. Entire organs cannot be printed yet. Figures 1 and 2 show an example of volumetric bioprinting with a heart. Complete hearts cannot be printed at this time. The figures do give a clear picture of the operation of the volumetric 3D bioprinter.

| Figure 2: As the tube is rotated, it is illuminated

from all sides with light in the shape of a heart. Thus a hologram of a heart becomes a real heart. |

| Figure 3: Volumetric 3D printing. A rotating tube

is illuminated with light. The cells in the tube harden when they hit the light. This is how a heart is printed. |

The volumetric bioprinter can print tissue from different types of organs. This can’t just be used to find a cure for diabetes. The printed tissue can also be used in the development of new medicines. Testing new drugs is a long and very expensive process. Testing is often done first on animals and later on humans. The printed organ tissue could potentially replace animal testing in the future. Subsequently, finding suitable patients for testing is a very time consuming and very expensive process. The printed tissue can be used to predict whether a patient is a good test candidate. This saves a lot of money and time in looking for the right test candidates. In short, printed organ tissue can replace animal testing in the development of new medicines and make this faster and cheaper.

In decades, hopefully, that printer will also be able to print entire organs. “The ultimate goal is to transplant the printed organs in the future, to replace (parts of) broken organs.” Ribezzi says. Hopefully this will make organ donors redundant in the future. “For patients with diabetes, this would mean that they will no longer be dependent on insulin or other drugs.” Before we get to that point, a lot more research needs to be done. “It’s possible to print something that has the shape of an organ with the right cells, but getting the cells to work is still a challenge at the moment.” According to Ribezzi.

Ribezzi and his team have thus received money to work on developing a volumetric 3D bioprinter. This printer will print organ tissues. These tissues will be used to test a drug for diabetes. In a few years’ time, these tissues will replace animal testing and accelerate the development of new medicines and make them cheaper. In decades, hopefully, we will be printing not just tissues, but entire organs. These printed organs will hopefully replace organ donors. All in all, Ribezzi and his team are busy finding a permanent cure for van Galen and all other patients with diabetes.

Translated from Dutch